What type of power do we need for our LED lighting units and systems? And how much of it? And how do we get it?

The answers to these questions are changing everyday with all the new technology being developed by stage lighting manufacturers across the board. Lighting units have better optics and are using brighter lamps. LED technology is constantly improving along the lines of Haitz’s Law. Using this new gear requires some rethinking when mixing with traditional fixtures makes things even messier—even as we need more and more constant or clean power.

Lighting gear that has electronics inside requires non-dimmed power, or “constant power.” Some people call this clean power. Though “clean power” is usually what the sound dept. wants. Constant power works for us just fine. What is this “constant power” and why do we want it? For that matter, what is “not-constant power?”

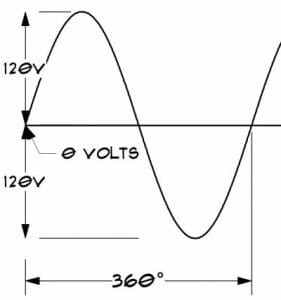

Power from the electric company comes into our facilities at a voltage between 100-240 Volts in the form of a sine wave of either 50hz or 60hz. The standard for North America (all of the US and Canada) and much of South America is 110-120 Volts at 60hz. Most other countries and continents use 220-240 Volts at 50hz.

Furthermore, the electricity coming into our theaters from the power company is delivered in AC (alternating current), measured in amps. (Most theaters in the US use lighting circuits rated at 20 amps, which is quite enough to kill you thank you very much.) Even if there are minor fluctuations in the power that gets delivered to a theatre from the electric company (or from a generator), this then is generally considered “constant” power, a steady 120V, 60Hz.

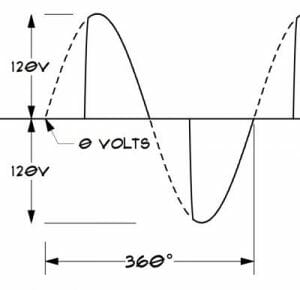

It used to be in theater lighting that we would limit the power to the lamps via using resistance dimmers. Holding back 100% of the power from the lamp, full resistance equals the lamp is off, up to offering no resistance (0% resistance), which allows the power to flow freely giving us a lamp at full brightness. Nowadays, we manipulate the sine wave instead. Current dimmers change the structure of the sine wave in order to dim our lamps more efficiently then resistance dimmers. The dashed line represents the full sine wave reaching 120Volts at 60hz (cycles per second). The solid line of this illustration represents a dimmer sending an adjusted pattern of the electrical energy sent to the lamps in our lighting units. The top and bottom sections of our standard sine wave is being cut nearly in half resulting with our lamp burning at approximately 50-60% of its potential full brightness. In other words, our light is “at 50.” The term for this particular pattern is called “forward phase dimming.” Other technologies include “reverse phase dimming,” and “sine wave dimming.” All of these involve the manipulation of the sine wave in one-way, or another.

It used to be in theater lighting that we would limit the power to the lamps via using resistance dimmers. Holding back 100% of the power from the lamp, full resistance equals the lamp is off, up to offering no resistance (0% resistance), which allows the power to flow freely giving us a lamp at full brightness. Nowadays, we manipulate the sine wave instead. Current dimmers change the structure of the sine wave in order to dim our lamps more efficiently then resistance dimmers. The dashed line represents the full sine wave reaching 120Volts at 60hz (cycles per second). The solid line of this illustration represents a dimmer sending an adjusted pattern of the electrical energy sent to the lamps in our lighting units. The top and bottom sections of our standard sine wave is being cut nearly in half resulting with our lamp burning at approximately 50-60% of its potential full brightness. In other words, our light is “at 50.” The term for this particular pattern is called “forward phase dimming.” Other technologies include “reverse phase dimming,” and “sine wave dimming.” All of these involve the manipulation of the sine wave in one-way, or another.

Unfortunately for us, all of these flavors of sine wave manipulated dimming will negatively impact the switching power supplies within our moving and/or LED lighting units. In fact, just about any device that contains electronics prefers a smooth sine wave—constant power. Dimmers parked at full are still limited in their ability to continually supply full power with a smooth sine wave. Which means that even if you pinky-swear promise to never dim a channel that an LED is plugged into, the mere fact that the circuit is run through a dimmer is enough to make it dirty, or non-constant, and unusable for a whole host of fixtures.

We have some choices to make in order to solve our power needs. Some solutions are being created and marketed by the dimmer manufacturers, and some involve modifying your own dimmers or circuits in house.

How do we add Constant Power for our LED and Moving Lights?

Dimmer manufacturers are making constant power modules that can be swapped with existing dimmer modules. These constant power modules can be a simple circuit breaker switch that is controlled solely at the dimmer rack, or, can be and on/off relay module that can be controlled remotely via signals from your control board. Those that wish to be able to reset electronic units without a trip to the dimmer room will prefer the switching relay module.

Dimmer manufacturers are making constant power modules that can be swapped with existing dimmer modules. These constant power modules can be a simple circuit breaker switch that is controlled solely at the dimmer rack, or, can be and on/off relay module that can be controlled remotely via signals from your control board. Those that wish to be able to reset electronic units without a trip to the dimmer room will prefer the switching relay module.

Solutions created in-house have included bypassing the electronics within a dimmer module and wiring straight to the circuit breaker. This might be particularly advantageous for those theaters that have dimmer modules that are nonfunctional and/or in need of repair. (As with anything involving the words “wiring” and “circuit breaker” please keep in mind that any act of that nature should only be done by fully trained, competent and authorized personnel.)

Solutions created in-house have included bypassing the electronics within a dimmer module and wiring straight to the circuit breaker. This might be particularly advantageous for those theaters that have dimmer modules that are nonfunctional and/or in need of repair. (As with anything involving the words “wiring” and “circuit breaker” please keep in mind that any act of that nature should only be done by fully trained, competent and authorized personnel.)

Case Study in a rental venue:

For the annual Stage Lighting Super Saturday workshop, held in New York City, manufacturers showing their equipment often request constant power. When theaters in which the workshop is held do not have constant power modules, Lite-Trol Services has come in and “strapped the dimmers.” In other words; Lite-Trol hardwired directly to the breaker to safely bypass the sine-wave altering electronics inside the dimmer modules of our hosting theater. Without their assistance, we would need to rent power distribution boxes and tap into the building power in order to supply constant power to the manufacturers displaying their electronic equipment. Not to worry, no dimmers were harmed during the workshop and they were restored afterwards.

For the annual Stage Lighting Super Saturday workshop, held in New York City, manufacturers showing their equipment often request constant power. When theaters in which the workshop is held do not have constant power modules, Lite-Trol Services has come in and “strapped the dimmers.” In other words; Lite-Trol hardwired directly to the breaker to safely bypass the sine-wave altering electronics inside the dimmer modules of our hosting theater. Without their assistance, we would need to rent power distribution boxes and tap into the building power in order to supply constant power to the manufacturers displaying their electronic equipment. Not to worry, no dimmers were harmed during the workshop and they were restored afterwards.

A third option is to bypass the power to the grid completely, and simply plug in fixtures to a standard building outlet in the wall.

Parts of this post appeared in a 2015 issue of Stage Directions Magezine article written by Scott C. Parker and has been updated here with revised information.